Donald Owens in the lab.

Diesel engines support much of the nation’s infrastructure — from trucks, buses, and trains, to ships, off-road equipment, and generators. However, these efficient work machines also have a severe environmental impact. There are currently almost 400 million diesel engines in the world, with nearly 20 million new ones produced worldwide each year, with each engine capable of producing tons of air pollutants in its lifetime. Diesel-powered vehicles and equipment account for almost half of nitrogen oxides and over two-thirds of particulate matter emissions from US transportation sources. HNO Green Fuels, Inc. (http://hnogreenfuels.com), a manufacturing, distribution, and R&D company out of California currently has a pilot-level product, which could potentially make diesel engines cleaner and even more efficient.

Particulate matter (PM) is essentially soot that’s created during an incomplete combustion of fuel. This is inherent in all diesel engines. The composition of PM includes sulfates, ammonium, nitrates, elemental carbon, carcinogenic compounds, and heavy metals. Ultrafine particulates make up 80 to 90 percent of diesel soot pollution. This is very bad because these particulates are small enough to penetrate lung cells. Diesel emissions contribute to ground ozone, which can severely irritate the respiratory and cardiovascular systems. The U.S. Environmental Protection Agency (EPA) has classified diesel exhaust as a potential human carcinogen.

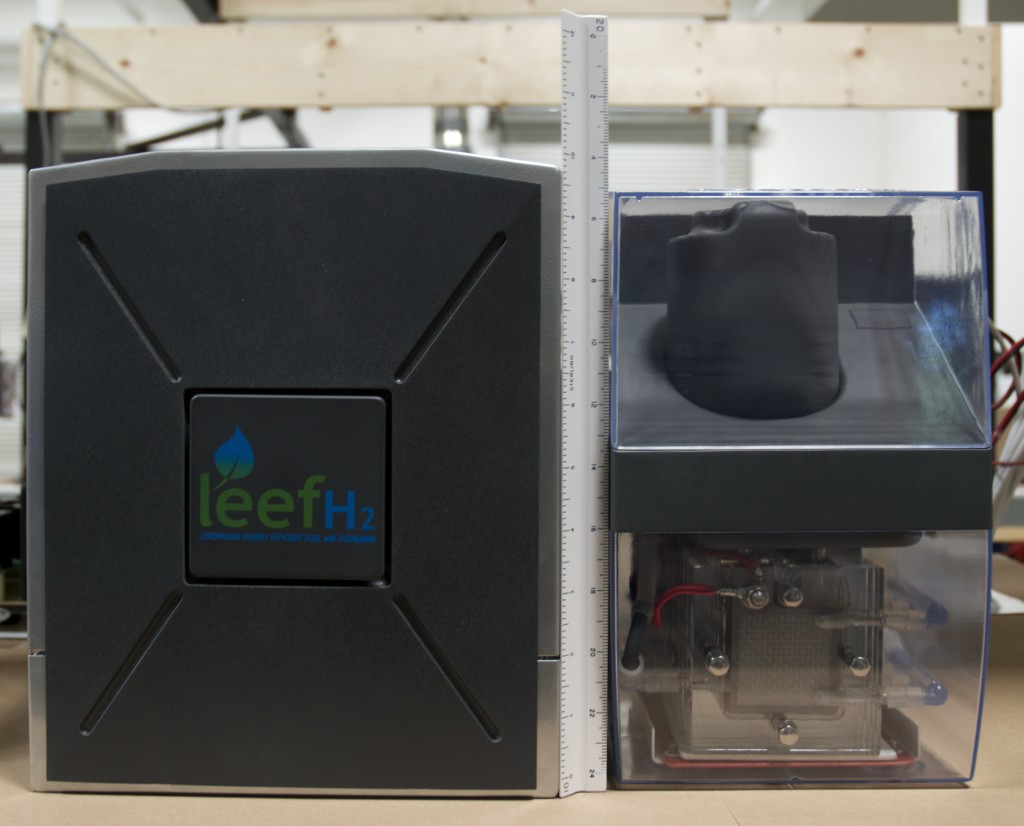

HNO’s proprietary technology is focused on reducing particulate matter emissions from combustion engines (mainly diesel and jet). Currently “Clean Diesel” engine technology typically uses a Diesel Oxidation Catalyst and a Diesel Particulate Filter (DPF) to reduce particulates from reaching the atmosphere. However, because the method of combustion has not changed with the “Clean Diesel” systems, a large amount of particulates are still created during combustion cycle and ultimately clog up the DPF. HNO’s Leefh2 (Leveraging Energy Efficient Fuel with Hydrogen) Diesel System takes an entirely different approach.

With Leefh2, the addition of hydrogen enhances the combustion flame in the combustion chamber of the engine, making the amount of unburned fuel exiting the combustion chamber significantly lower than with normal diesel combustion. As an additional environmental benefit, the Leefh2 process also produces breathable oxygen that is released into the atmosphere, just like an actual leaf. Leefh2 system includes an engine on-board diagnostic (OBD) interface and wireless transmitter module, so that engine data can be sent seamlessly to a Fleet Management system. This is important because the addition of hydrogen increases fuel efficiency depending on RPMs of the engine. For example, normal diesel engines are very inefficient when idle. Using Leefh2 when idling can reduce fuel usage by at least12% or more.

If you’re wondering where the hydrogen comes from in the Leefh2 system that enhances the combustion flame, the answer is simple — water. Water (H2O) contains hydrogen and oxygen. In the Leefh2 system the hydrogen splits off from the water and is the catalyst used by the Leefh2 to increase the combustion efficiency of the diesel fuel or any other hydrocarbon-based fuel, for that matter.

HNO stands for “Hydrogen and Oxygen.” HNO founder Donald Owens tells a pretty down-to-earth story about the history of Leefh2. Owens earned a degree in Mechanical/Electrical engineering years before, but stepped away from engineering to earn his law degree and practice patent law. The way he tells it is very nonchalant, given the potential impact of Leefh2.

“Years ago I read this little article…they were selling this book for $69 about how you could use hydrogen to give your car more fuel economy,” Owens said. He bought the book and eventually he built his own device, which utilized the electrolysis of water, which seemed to work well but was rife with issues. “It was a mess and was going to be impossible to commercialize. One night I was on the internet, trying to solve one of the many problems I had related to this thing, and I ran across something called an electrolyzer, which takes distilled water and breaks it up into hydrogen and oxygen with no mess,” Owens said.

Normal electrolysis uses terminals to pass electricity through a water based electrolytic solution thereby splitting the solution into the atoms from which it is made. With an electrolyzer, the hydrogen and oxygen gases are split from water without using an electrolytic solution. Electrolyzers are typically used in large-scale hydrogen production. However, with the Leefh2 system, only a very small amount of hydrogen is necessary to make a big difference in a diesel engine.

The first tests on the effectiveness of Leefh2 have shown some pretty amazing results. Tests in EPA approved laboratories have shown a nearly 50% reduction in PM emissions in diesel engines (HNO believes a 90 – 95% reduction is possible). As mentioned above, 12% reduction in fuel usage was realized during the idling of diesel engines. Furthermore, even though HNO isn’t going after the gasoline consumer market at the moment, 24% in fuel saving was achieved with certain classes of gasoline engines when conducting an EPA standard Highway Fuel Economy Driving Schedule test.

Owens mentioned having talks soon with a certain high-level government body about joint testing, but declined to give specific details.

Currently, HNO has eight patents (with more pending) for the Hydrogen Supplemental System. They have also submitted a patent application for Increasing Combustion Efficiency and Reducing Particulate Matter Emissions in Jet Engines. The commercialization of Leefh2 may well be close at hand, but it is also highly contingent on various factors. For example, the commercialization and product line will depend heavily on the pilot tests that are required for specific engine types. It should also be noted that the production capacity for supporting the implementation of the Leefh2 system on a large scale is not yet present. One has to ask, where will all the electrolyzers come from?

Despite obstacles, HNO may very well be on the brink of something revolutionary. HNO’s website reads: “ So as we seek to improve the combustion efficiency of every single combustion engine on earth, thereby reducing fuel consumption and particulate matter emissions, we will by default add millions of tons of life-sustaining oxygen to the atmosphere……which MAY…just MAY help Mother Nature in the repair of our fragile planet from the effects of global warming.” Oxygen depletion and its relation to climate change is an ongoing field of research with many unknowns. Increases in atmospheric and oceanic oxygen content have been historically associated with bio-feedback that takes in CO2, leading to a climate cooling effect.

Whether or not Leefh2 becomes a success, HNO’s work and research has shed further light on a critical environmental and public health issues in the U.S. Particulate Matter emissions are dangerous and must eventually be dealt with in order to create a safer and cleaner way of life.